The construction industry is going through a sea change. Projects are becoming bigger, more complicated, and increasingly data-driven. Consequently, AEC firms are under pressure to improve coordination, reduce risk, and make better decisions much earlier in the project lifecycle. It is here that the concept of a digital twin in the construction process is gaining serious traction.

The digital twin is no longer a concept of the future but is an applied solution based on BIM models, turning those into dynamic and connected data assets. In the right context, properly deployed BIM-driven digital twin workflows will drastically improve preconstruction outcomes in terms of visibility, accuracy, and coordination before construction starts.

It is about time that knowing how digital twins work in construction and support pre-construction planning became core knowledge for modern AEC organizations.

What is the Impact of Digital Twin Technology in the Construction Industry

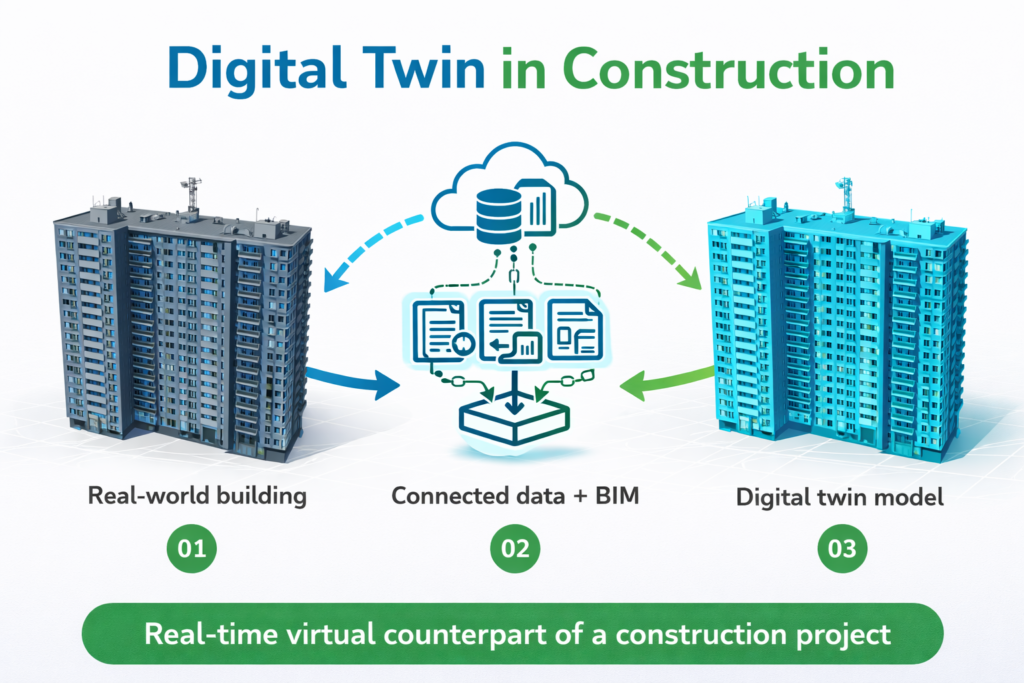

In its most basic form, construction technology involving a digital twin represents a reproduction of a physical object that develops over time along with its physical counterpart. This replaces static models of representation, as a digital twin provides continuous updates on project data, design changes, and performance information.

In construction scenarios, digital twins normally start in a format called BIM. In the format, there is geometric and non-geometric data concerning building designs and quantities. When BIM information is integrated with schedules and cost information, alongside project intelligence, a digital twin is developed that is reliable for decision-making.

Thus, an overview of the Digital Twin construction always begins with BIM. However, BIM is not limited to 3D visualization.

From BIM Models to BIM-Driven Digital Twins

To fully understand the value of digital twins, it is important to clarify their relationship with BIM. BIM provides structured, data-rich models that represent design intent. A BIM-driven digital twin takes this information further by linking it with time, cost, and performance data.

During preconstruction, this integration allows groups to virtually simulate scenarios, risks, and alternatives. This means that decisions are no longer being made based on assumptions.

The importance of this link between BIM services and digital twin integration is what gives digital twins special value in early project phases.

Why Digital Twins Matter in Preconstruction Planning

Pre-construction is where the majority of all the risks involved in a construction project come into play. Most of the mistakes that come up during the initial stages lead to rework, delays, and cost overruns. Digital twins assist in mitigating the risks through better clarity.

By employing a digital twin, different construction project preconstruction groups can:

- Visualise design intent with greater accuracy

- Analyse constructability issues early

- Coordinate disciplines more effectively

- Validate schedules and sequencing

- Improve confidence in cost and quantity data

Equally important, preconstruction planning technology enabled by digital twins empowers teams to transition from being reactive problem-solvers to proactive planners.

Improving Coordination Across AEC Teams

Construction is burdened by one of the biggest challenges: aligning architects, engineers, contractors, and consultants. Fragmented data and disconnected workflows commonly lead to miscommunication and design conflicts.

A digital twin in construction acts as a single source of truth. All the stakeholders work from one coordinated model, reducing ambiguity and misunderstandings. This is highly useful during the multidisciplinary coordination involving architectural, structural, and MEP systems. It also paves the way for smoother workflows among different disciplines involved in project execution and can reduce the number of RFIs and change orders later in the project for AEC firms.

Enhancing Construction Data Management

Construction projects involve huge volumes of data. Access to this information with efficiency plays a decisive role in decision-making, and in operational control, and risks. Conventional methods generally depend on pieces of unconnected documents or spreadsheets. These are hard to keep consistent.

Digital twins significantly enhance construction data management by bringing the information together in one connected digital space. The data on quantities, schedules, and design changes remains tied to the model for accuracy throughout the project’s lifecycle.

As a result, teams manage information flow better and minimize the risk of working with obsolete or contradictory data.

Digital Twin Use During Early Cost and Risk Analysis

“The accuracy of cost planning relies on good data. BIM quantities combined with schedule and cost data enable digital twins to help preconstruction teams analyze the budgeting impact.”

Such a capacity enables teams to:

- Test design alternatives against cost constraints

- Identify high-risk elements before procurement

- Improve confidence in early-stage estimates

As a result, digital twins strengthen financial planning and support more informed investment decisions for clients and developers.

Supporting AEC Digital Transformation

Adoption of digital twin is part of a broader AEC digital transformation happening in the construction industry. Firms are increasingly moving from siloed processes to integrated data-driven workflows.

It fuels this transformation by knitting design, planning, and execution together through a common system. This approach enhances transparency and accountability, allowing true collaboration across disciplines.

To AEC organizations, the adoption of Digital Twins is not about adopting new technologies; rather, it is an evolution in project delivery.

Overview of Digital Twin Construction at Different Levels of a Project

While digital twins offer extensive benefits during pre-construction, the benefits are seen across the total project cycle.

- Preconstruction: Testing scenarios, coordination, and validating costs

- Construction: Progress tracking, issue resolution, sequencing analysis

- Handover and operations: Accurate Asset Data for Facility Management

This continuity gives the digital twin a new function, turning a normally fleeting concept into a long-term project asset.

Common Tools for Supporting Digital Twin Workflows

Digital twins rely on robust technology ecosystems. BIM authoring and coordination platforms form the foundation, while collaboration and data platforms support integration.

Commonly used tools include:

- BIM authoring software for model development

- Coordination platforms for clash detection and issue tracking

- Cloud-based Environments for Data Sharing and Collaboration

These tools, when used together within a set of workflows, support consistent and reliable digital twin implementation.

Challenges to Consider When Adopting Digital Twins

However, despite the benefits being significant, digital twin adoption is a planning activity. Lacking proper processes, the teams involved could be at a loss.

Some of the key considerations include

- Defining data ownership and update protocols

- Aligning digital twin workflows with BIM standards

- Training teams to interpret and use model data effectively

Addressing these factors early on helps ensure digital twins have real value to add to an organization rather than remaining underutilized models.

Why BIM-Driven Digital Twins Enhance Preconstruction Outcomes

Finally, the essence of digital twins is that better decisions can be made before the start of the construction process. This is facilitated by the ability to use BIM information while connecting it to other areas such as time, cost, and performance.

In order to successfully implement digital twins within construction strategies, it is fundamental to ensure their accuracy by being based on proper BIMs. Therefore, having this groundwork basically makes digital twins useful tools for risk reduction.

The Future of Digital Twins in Construction

Similarly, as technology advances, digital twins will likely play an even more important role in construction processes. Advances in automation technology and real-time data integration will further increase their value.

Firms that adopt AEC business models that invest more in BIM-based digital twin methodologies will be able to navigate complexity, manage risks, and maintain consistency over time.

How AEC Firms Can Turn Digital Twins into a Preconstruction Advantage

Digital twins represent a natural evolution of BIM and preconstruction planning. They digitally connect data, people, and processes in a single digital environment that supports smarter decisions.

With construction projects continuing to become more complex and margins tightening, utilizing a digital twin on a construction project is no longer optional. It is a strategic differentiator that defines how successful projects will be planned and delivered.

FAQs

A construction digital twin can be understood as a dynamic digital representation of a physical asset, resulting from the integration of BIM data and project information supporting planning, coordination, and decision-making activities.

While BIM focuses on creating structured models, the digital twin connects the BIM with time, cost, and performance information throughout the project’s lifecycle.

They provide early identification of risks, improve coordination, and validate cost and schedule assumptions before construction begins.

No. Digital twins build on BIM. A BIM-driven digital twin is hinged on correct BIM models.

The use of digital twins will be most apt for projects with high complexity, numerous stakeholders, a hectic schedule, and high levels of coordination.